Description

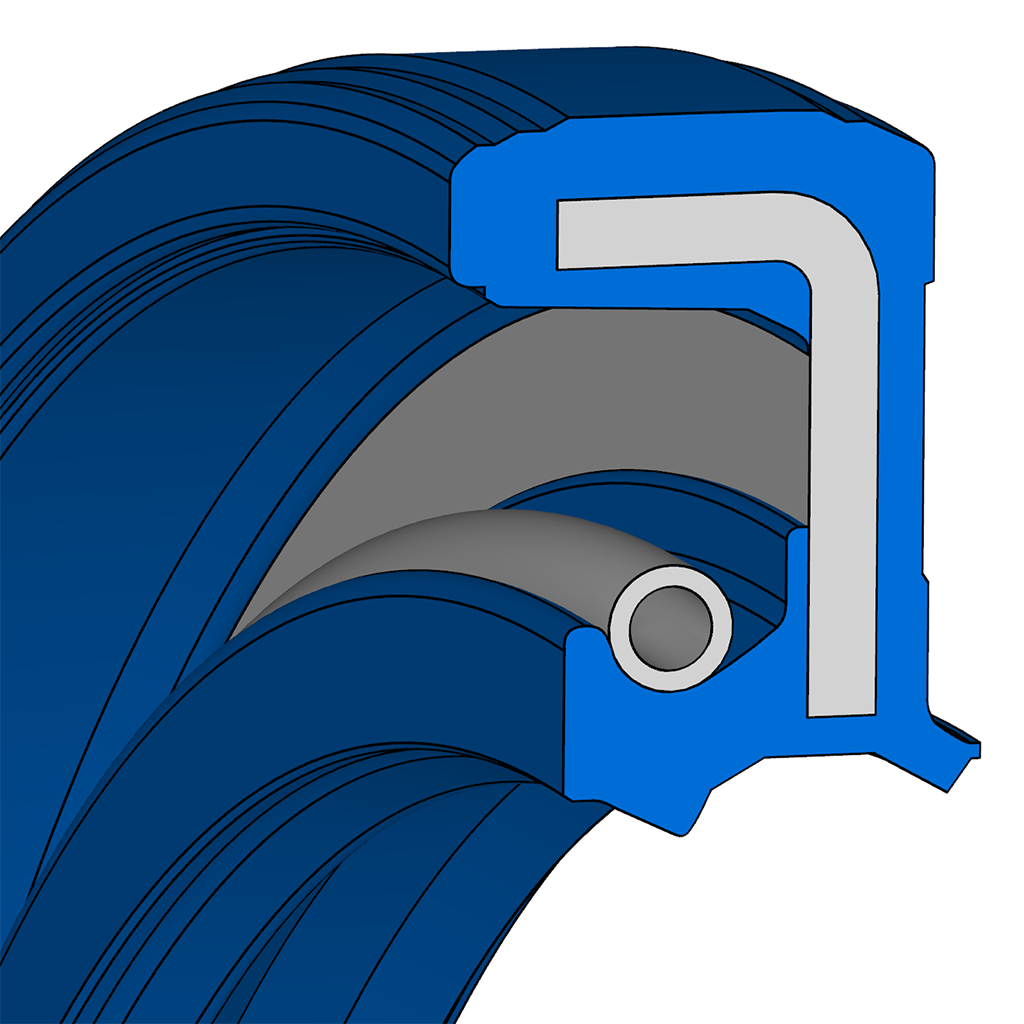

- With tension spring

- With protective lip

- Shortened sealing lip

- Rubberized outer jacket

- Advantages

- Downloads

- Function

- Applications

- Very good static sealing effect with low-viscosity or gaseous media.

- Low friction (up to 50% lower frictional torque than commercially available seals)

- Compensation of thermal expansion, e.g. in light metal housings, very good sealing effect with greater roughness and split housings

- Use at high speeds

- Longest service life

- Dynamic sealing of rotating shafts, independent of direction of rotation

- Optimized sealing lip design for pressure loads

- Good static seal between sealing lip and shaft at standstill

- Protective lip against dirt accumulation from outside

- Rubberized outer jacket ensures tight fit and seal to housing bore

- Self-retaining

- Reduced friction leads to a lower temperature level in the sealing gap

Most commonly used in the following applications:

- Hydrostatic drives