Description

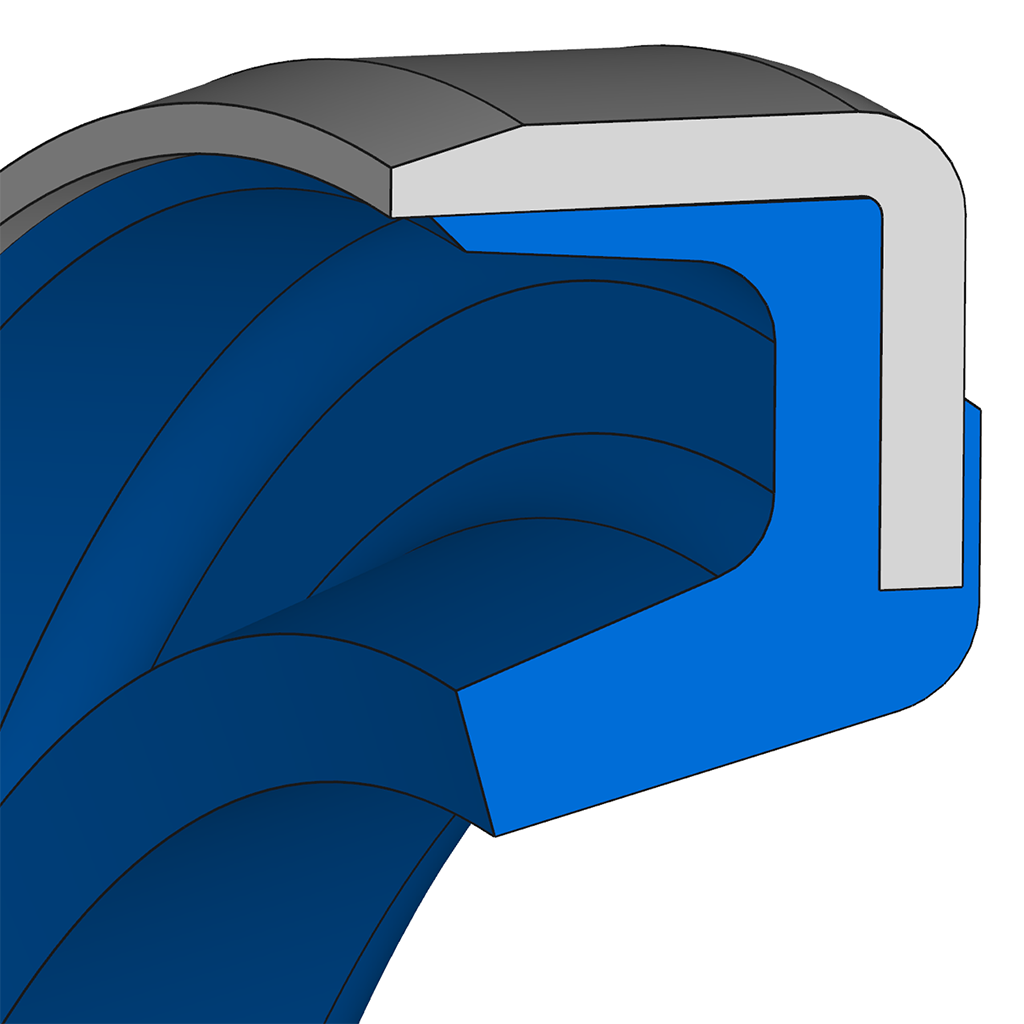

- Without tension spring

- Without protective lip

- Open metallic outer jacket

- Advantages

- Downloads

- Function

- Applications

- Low friction

- Longest service life

- Dynamic sealing of rotating shafts, independent of direction of rotation

- Simple sealing against grease or additional sealing against dust and dirt accumulation

- Metallic outer jacket ensures tight and precise fit

- Self-retaining

- Only limited static sealing between sealing lip and shaft at standstill

- Design without tension spring creates less friction, but also less sealing effect

- Limited sealing of low-viscosity and gaseous media and in split housings

- Not recommended for oil sealing

- Additional guling of the seal into the housing is recommended

Most commonly used in the following applications:

- Electric vehicles

- Sealing of swivel bearings and actuators