Description

Freudenberg Sealing Technologies offers axial shaft seals and V-rings for different operating conditions, both as standard and custom solutions. The axial shaft seals are an upstream element protecting the interior space of the housing against dirt, dust and spray water, and act reliably and safely even in aggressive environments and axial movements.

Axial shaft seals from Freudenberg Sealing Technologies

Axial seals are indispensable components in the complex world of machines and systems. These special seals ensure that components are reliably sealed in the axial direction. They protect against external contamination, prevent leaks and contribute significantly to the longevity and efficiency of machines. Axial shaft seals are used very successfully in drive technology and mechanical engineering, for example in electric motors, construction machinery, roller bearing housings, pumps and washing machines.

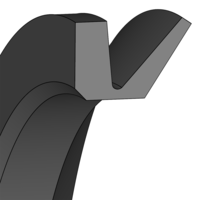

Simple axial seals

The axial seals from Freudenberg Sealing Technologies are a simple sealing element with an excellent sealing effect that reliably protects against dirt, dust, grease and splash water. They are particularly suitable for use in combination with radial shaft seals.

The axial shaft seals have an excellent dynamic sealing effect and low requirements on the mating surface in terms of surface quality. An additional axial stop is not required.

Design and variants of axial shaft seals

We offer different variants of the axial seal. These consist of two components: a coated metal ring and an elastomer sealing element vulcanized from the mould. The metal ring protects the elastomer seal against damage, serves as a holder and support for the elastomer seal and also acts as a flinger. The elastomer seal is expanded onto the metal ring and is also held in place by the axial flanged collar.

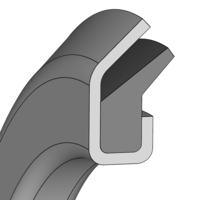

Axial seals as labyrinth seals

In applications with very high requirements, the axial shaft seal is also used as a labyrinth seal. For this purpose, the metal ring on the outer casing is extended in the axial direction. In combination with the circumferential groove in the axial mating surface, this forms an additional labyrinth seal.

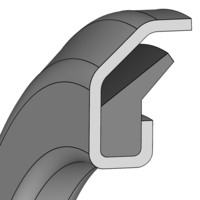

Centrifugal effect supports sealing function

The VRM axial seal generates a centrifugal effect through the metal ring, which supports the already very good sealing function. As a result, dust, dirt and splash water are thrown away. As the circumferential speed increases, the elastomer sealing element moves outwards due to the centrifugal force and reduces the contact pressure point. Above a certain circumferential speed, the sealing lip lifts completely away from the metal mating surface, so that the axial seal then only serves as a gap seal and flinger ring.

((H2)) Axial seals from our range

Our range of axial seals in various diameters and installation dimensions including product and material data sheets, ordering options, prices and availability as well as dealer contacts can be found in our FST E-catalog.